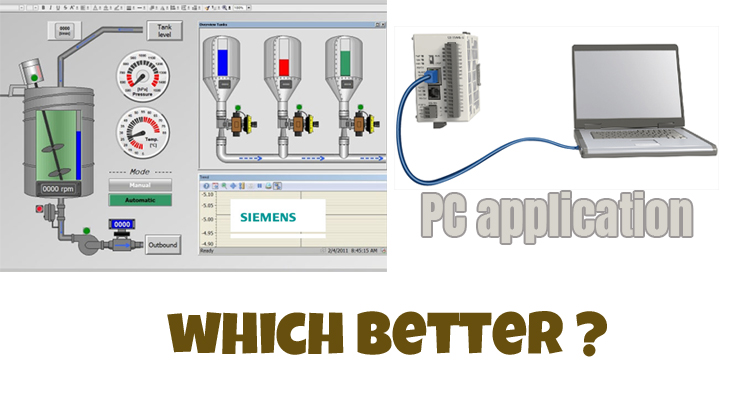

One of the questions you usually ask me is a Siemens HMI screen or a PC application that connects to the PLC? What is better?

The answer, as almost always is… it depends.

Siemens HMI or a PC application

By elaborating the answer a little more, we can see the advantages and disadvantages of each one.

Siemens HMI: basic and comfort panels

Siemens HMI screens are primarily intended as HMI, that is, as an interface between man and machine to be able to view states and input of command and certain data. Furthermore, Siemens HMIs are intended for an industrial environment.

Click here if you need the spare part 6AV2124-0QC02-0AX0 by Siemens

They are tactile, with physical buttons in some cases with a high degree of protection against what we can find in the industry (typically IP65).

They are robust, and in general, they tend to give little war.

They also require practically zero maintenance beyond keeping the screen clean.

Connecting these displays to Siemens PLCs is almost trivial.

Its programming using WinCC Flexible is designed to be as intuitive as possible.

You have WinCC Flexible 2008 for older existing displays, as in the TIA Portal for modern ones.

Finally, the mobile screens that will allow you to have wireless controls, which, in some cases, can be useful.

What are the drawbacks of Siemens HMIs?

Although it is true that more and more things can be done with the screens (the comforts have more capabilities than those of the Basic series), they are relatively corseted to what Siemens understands is necessary to manage the lines.

In other words: in exchange for having a reasonably simple development interface, these screens do not allow you to perform tasks that may be necessary in your process. At least in a simple way.

Regarding the price, because in general they are not economic elements.

Depending on the dimensions and features, they can range from a few hundred euros to several thousand.

But to put a reference, a small basic screen and in B / W are a few hundred euros.

It is small, in B / W and with not much resolution.

If we go to the largest screens, 15 ″ comfort, we are talking about several thousand euros.

As you can see, they are not economic elements.

Application on a PC

On the other hand, you have the possibility of mounting a PC and creating an application that runs on it and that communicates with the PLC.

There you have a greater range of possibilities since you can buy commercial software (such as WinCC, iFIX etc) or create your own application with a free suite such as Visual Studio Express and communicate through TCP, OPC, etc.

The advantage of these alternatives over Siemens HMI panels is fundamentally in terms of their versatility.

There are no limits since on a PC you can program whatever you want (especially using Visual Studio style environments).

The screens can be much larger without the cost increasing enormously and communication with other equipment in general will be much easier (printers, scanners, servers, databases, etc.).

Disadvantages of mounting a PC application

The main disadvantage of mounting a PC application to communicate with a PLC is that Siemes panels are much more suitable for simple and medium applications.

A PC offers many possibilities, but it is not always the most suitable.

First because a PC gives more stability problems. Come on, it hangs from time to time (thanks Microsoft!).

PCs, even though they are industrial, have a greater maintenance in terms of cleaning, they have to be in cooler places than the panels, you need a keyboard and mouse to handle them comfortably … in short, they are not as robust and simple as the panels. .

Also, the programming is generally going to be more complex.

Even in WinCC it will not be as user-friendly and easy to understand as it is in WinCC Flexible.

On the other hand, WinCC, iFIX, Wonderware development software licenses are not exactly given away either. In general, they are quite expensive, reaching many thousands of euros depending on the number of variables to be handled and the manufacturer.

A very common combination is an OPC server (whatever the manufacturer) and adding an application made in Visual Studio (in VB.NET, C # etc).

It is a good option from the moment that you have full versatility and the cost of the license is content (generally below € 1000).

The disadvantage of this case is that you have to program absolutely everything.

So which do I choose, Siemens HMI or PC application?

After this little exposition, the question is clear.

Voucher. We have a thousand possibilities between choosing a Siemes HMI or a PC application:

But what about mine?

Unfortunately there is no generic answer and we return to the starting point: it depends.

If you are going to operate a machine in which the HMI does not